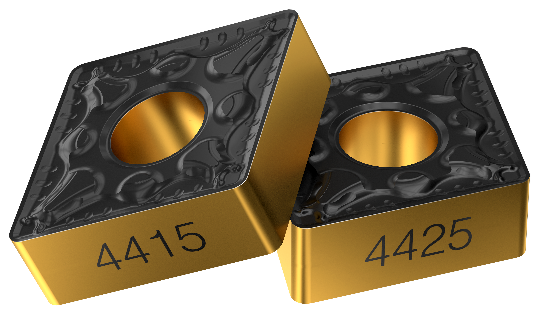

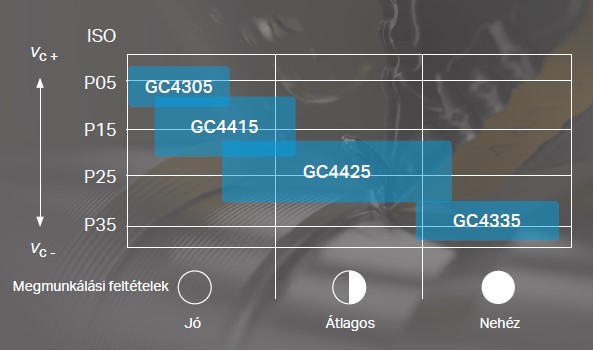

NEW STEEL TURNING GRADES, GC4425 and GC4415

2023-08-21

Today, depending on the market demand, reducing production cost or increasing output is a top priority for making steel turning operations more efficient. Common challenges often involved are to increase metal removal rates, reduce cycle times and to minimize material waste, but can also include optimizing tool inventory and to operate at lower capacity without compromising process security.

Sandvik Coromant offers a complete, market-leading steel turning offer, developed to help your business thrive and production to reach new levels. The new generation steel turning grades are enhanced in every aspect, from tool life to wear and heat resistance, offering secure, efficient and productive steel turning.

The new grades are solutions for the following turning challenges:

- You can increase your part pro cutting edge number

- You can increase the cutting speed

- You can reduce the cycle time

- You can minimize the waste

- You can optimize your tool inventory

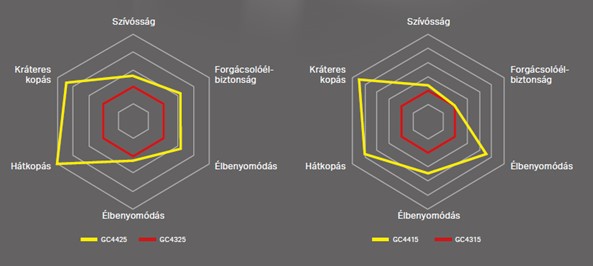

Toughness and wear resistance combined

New substrates with a unique combination of good toughness and resistance against plastic deformation offer a reliable performance. The cobalt enriched surface gradient adds to security.

New post-treatment

Improved post-treatment lifts the performance in intermittent cutting operations. The bright yellow top TiN coating on the insert flank allows for easy wear detection.

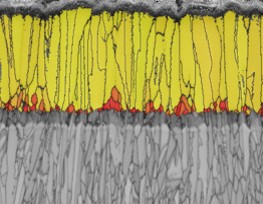

Second generation Inveio technology

With the introduction of the second generation Inveio® technology, the benefits of uni-directional coating have been further developed. Improved crystal orientation makes for an even more consistent performance and significantly improved wear resistance and tool life.

Sustainable steel turning

An average of 25% tool life increase combined with a reliable and predictable performance helps minimize both insert and workpiece material waste, necessary preconditions for sustainable machining. Moreover, its carbide substrate contains a high proportion of recycled carbide material, making them one of the most environment-friendly grades.

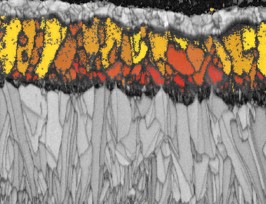

Conventional CVD alumina coating with random crystal orientation.

With Inveio®, every crystal in the alumina coating is lined up in the same direction, creating a strong barrier towards the cutting zone.

First choice for steel turning

Refined in every aspect: